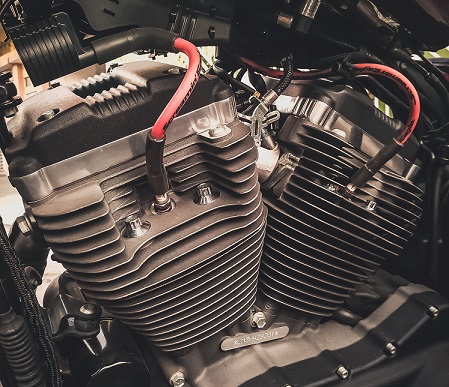

Internal Combustion Engines (ICE) in motorcycles come in various configurations and displacement capacities. Yet, the engine parts are broadly the same.

The main parts of a motorcycle engine include:

- Cylinder head

- Piston and Cylinder

- Crankshaft

- Crankcase

- Rocker arm and Valves

- Camshaft

- Spark Plug and Ignition system

The most basic engine is a vertical single-cylinder two- or four-stroke and found in entry level to mid-range displacement production machines.

Next in line are the twin cylinders (inline, vertical or parallel) that have been in vogue for a long long time. In fact, the world’s first production twin-cylinder motorcycle was the 1894 Hildebrand & Wolfmüller.

The most successful straight-twin motorcycle in motorcycle history is the 500cc 1938 Triumph Speed Twin.

Bigger displacement engines can be V-shaped or horizontally opposed. High end multiple in-line cylinder (3-, 4-, 5-, & -6) motorcycles have also been commercially produced by various manufacturers.

We take a look at the components and technologies inside an engine.

Cylinder Head

Starting from top of the engine is the cylinder head that is bolted on to the engine cylinder/block. Cylinder and cylinder head together form the combustion chamber.

Cylinder heads in most older pre 80s motorcycles were made of cast iron, modern production motorcycles have them in aluminium alloy.

As cylinder head acts as the top half of the combustion chamber, in four-strokes, the internal design is most round or hemispherical.

It can host 2-, 3-, 4-, or 5- inlet/exhaust valves and at least one spark plug depending on job description. To increase performance and efficiency, some engines have two spark plugs per cylinder.

In a four-stroke set-up, the cylinder head design gets complicated depending on the number of cylinders and other components that go with it like rocker arms, camshaft, camshaft pin, a sprocket, cam-chain, inlet/exhaust valves, springs, locks and venting systems besides inlet and exhaust manifolds.

Modern day motorcycle engines are designed as overhead valve (OHV) type. In some of the pre-WW II engines, there were instances of side valve arrangement.

Two-stroke cylinder heads are simple in design as they just host the spark plug.

Piston And Cylinder

Piston is cylindrical alloy part that moves up and down in the cylinder and is responsible for transforming kinetic energy (created by igniting fuel/air mixture) into mechanical energy.

The piston has grooves for cast iron rings and usually there are three grooves to accommodate the three piston rings.

The top ring ensures airtight environment for the piston during combustion for maximum pressure.

The middle (second) ring is responsible for catching any oil that may be on the cylinder wall and the bottom one is the oil ring guides the oil through holes in the piston and down into the bottom end.

The piston is connected to a connecting rod by a hollow gudgeon pin. The other (big end) of the connecting rod is connected to the crankshaft.

The cylinder is usually made out of cast iron but now aluminium cylinders with liners are also being used.

With advances in materials and space-age coatings, unique geometries and remarkable sealing technologies, engines are more durable, long lasting, and less prone to failure.

Some manufacturers like Honda (acknowledged as one of the finest motorcycle engine designers) went ahead and designed unique oval pistons with the idea of getting more air/fuel into the cylinders to help ramp up power output!

Crankshaft

One of the heavier components in the engine responsible for building inertia and momentum is the crankshaft.

Crankshaft is designed to convert linear (up and down) motion of piston into rotational motion. Forged steel is used to make this part and it is machined by CNC machines and balanced to precision.

In some highly advanced motorcycles like Yamaha RD500, you have twin crankshafts in the V4 engine.

Crankcase

To accommodate important parts like the crank, pistons, cylinder, oil pump, pinions, gears and other components in an hermetically sealed environment, you need a strong and dedicated housing.

This housing is called crankcase (the lower part below the cylinder) and forms the largest cavity in the engine.

Irrespective of the number of pistons, the crankcase that is casted out of aluminium alloy is always a single unit and will have mounts for all the internal components like crankshaft bearings, internal oil routes, oil seal holders and bushes among other bolt-on parts.

Crankcases are cast in two halves. Gaskets are also used when the cylinder is assembled along with other parts like the cylinder, cylinder head to ensure there are no leaks.

Fresh engine oil is poured in from the right hand side of the crankcase through the opening provided. Oil seals or ‘O’ rings are placed in strategic points inside the engine.

When combined with a host of other parts it becomes a multifunctional unit — especially in modern motorcycles where the transmission portion is also integrated.

In pre-, post-war motorcycles the transmission was a separate unit and was connected to the engine through sprocket and primary chain with a clutch basket mounted on the gearbox shaft.

Engine oil is stored in the crank case and depending on whether it is of dry sump or wet sump design, engine oil is circulated with the help of oil pumps.

There’s also an oil filter in the sump and an opening for allowing used/burnt oil to be removed. In older oil-in-frame (OIF) bikes, there was a separate oil tank. The crankcase also has a breather arrangement.

Rocker Arm And Valves

It’s a small but important component that you could think of as a doorman whose job is to open or close doors.

Rocker arms are guided by camshafts to open inlet/exhaust valves.

One end of the rocker is guided by the lobe of the camshaft while the other end pushes the spring loaded valve to open.

In pushrod type of engines, there would be pushrod, pushrod tubes, cam followers, guides and assorted timing gears for operating them.

Camshaft

Camshaft determines how much air goes in and comes out via the opening and closing of valves – one of the most important working components of a four-stroke engine

The camshaft is dependent on the crankshaft for the ignition timing, opening/closing of valves.

Both the sprockets — one on camshaft and the other on crankshaft are connected by a timing chain.

The lobes on the camshaft are profiled to offer the lift required and are specific to each type of engine. Unless the engine uses variable valve technology, the lift arrangement is usually fixed. High tech engines may use actuators for valve lifting.

In pushrod type engines, a set of pinions and cams are used to operate the valves.

Timing Chain/Sprocket

There’s a sprocket on the crankshaft that connects the sprocket of the camshaft using a timing chain.

When the engine is cranked, the movement of the crankshaft for opening and closing of the valves is determined by the camshaft lobs besides the precise ignition firing point. In two-stroke engines, this arrangement is not required.

Spark Plug and Ignition system

Without a high voltage spark, you cannot start an engine. The job of igniting the air-fuel mixture in the engine cylinder lies with the spark plug/s. The spark plug gets its 12,000-25,000 volt input from a high tension ignition coil.

The timing for the spark has to be precise and this is done by an electronic capacitor discharge ignition (CDI) unit. A pick-up coil sends the appropriate signals to the CDI unit.

In the pre-electronic era, mechanical contact breaker units were used with advance retard mechanisms. In modern machines, it is done by the electronic brain.

Electrical power supply for this comes from the alternator/dynamo or battery.

Other Supporting Systems

For an engine to run smoothly, there are many supporting system functions to operate. Here, we also discuss few of the main systems important for the motorcycle engine.

Fuel Supply

Carburettors have been used for a very long time to mix and pump air-fuel in a specific ratio and volume into the inlet manifold. This mechanical device works on the principle of manipulating air pressure to create the Venturi effect and is considered as the old school analog option now.

Since 80s, more and more motorcycle are being fitted with a throttle body with injector (fuel injector) that uses various sensors and electronic management systems to determine how much fuel is required. The system is extremely reliable and advanced requiring very little attention.

Engine Starters

To start a motorcycle engine, the motor has to be cranked. This is done by a kick-starter lever or electric starter motor.

Cooling Systems

Engines can get hot when working and overheating will cause the engine to seize and damage internal components.

There are different type of cooling systems. While basic entry level motorcycles are mostly air-cooled, some may have an oil cooling arrangement like a small radiator.

Bigger or performance motorcycles are getting coolant based systems similar to those in cars.

A radiator, thermostat valve controlled electric fan, coolant reservoir, rubber hoses, water pump will be among the hardware. In this case, the cylinder design is of jacket type with designated pathways for the coolant to circulate.

Air Filter

To ensure contaminant-free air entering the engine, there’s air filter fitted to the carburettor or fuel injector.

For a detailed overview, check out our post here on what air filters do.

Exhaust

Burnt gases have to be expelled and high decibel cacophony resulting from the combustion contained. This is where a silencer system and catalytic converter set-up work together.

Here is detailed post on motorcycle exhaust for you.

Transmission

Modern motorcycles crankcase house the clutch assemblies, transmission gears, shafts and other hardware.