The last thing you would want to experience is a stalled 2-wheeler refusing to start in the middle of a busy road. This can happen for many reasons. Some are simple, some are complicated and some are outright funny or ridiculous!

Interestingly, there are easy fixes but finding faults and repairs sometimes can be time consuming and expensive in extreme cases.

Problems with engine starting usually don’t happen overnight. Both internal and external factors can be responsible for the engine to stall and not restart.

Engine starting problems can be pinpointed to areas like fuels, batteries, oxidation, ignition timing, or component failures.

We have classified the problems here broadly as:

The most effective way to identify and solve the problem is to use the rule of elimination and common sense.

We take a look at 25 reasons for an engine refusing to start and suggest how to go about it.

Fuel Problems

Modern unleaded fuel are made with petrol blended with ethanol. Ethanol being hygroscopic tends to absorb moisture and that can cause a plethora of problems for the 2-wheeler.

#1: No Fuel

It’s common sense that if your motorcycle or scooter runs out of fuel, the engine will stall and not start no matter how hard you try.

If your 2-wheeler doesn’t have a fuel gauge or the gauge doesn’t work, check the fuel level in the tank by opening the cap as you would do when going for a refill. Once the fuel tank is topped up sufficiently and fuel flow to carburetor or fuel injector is resumed, the engine should fire up easily after a few cranks.

#2. Stale Fuel

In motorcycles or scooters that have not been used for weeks or months, fuel inside the petrol tank will eventually lose its combustion capabilities. Stale fuel will have to be replaced totally with fresh supplies. It’s advisable to thoroughly clean the fuel tank and check the condition of the fuel tap and filter. Clean or replace as necessary.

#3: Fuel/Water Contamination

During monsoons, there’s a tendency of petrol-ethanol blends to absorb extra moisture from the air. Contaminants like this that mix with fuel will create all sorts of engine starting problems. Even a single drop of water inside the engine can cause it to malfunction.

In a worst case scenario, rain water may find its way into the fuel tank if the tank cap seal is weak.

Water in fuel will short the spark plugs and they will have to be replaced for the engine to start easily.

Besides, you will have to get the fuel tank cleaned and dried out before it can be re-used with fresh fuel.

#4: Fuel gumming

Due to long periods of dormancy, ethanol blended petrol will stagnate and lose its potency, and left over for longer periods, it will dry up and the residue sticks to surfaces like gum. The process is called gumming and block the carburetor jet passages. If this happens, you are looking at many unpleasant hours of clean up.

If you are not planning to use the 2-wheeler temporarily and want to avoid gumming of fuel, it is advisable to drain out the fuel completely. Always, use fresh fuel to ensure trouble-free service.

#5: Fuel Taps/Petcocks

Fuel supply to the engine is controlled by a fuel tap. Most fuel taps have a sludge collector bowl that needs periodic cleaning. If choked, it will not allow fuel to pass through. In the case of external fuel filters, check if it is clean or clogged. If clogged, replace it.

Some scooters and motorcycles have diaphragm vacuum operated fuel taps. There’s a thin rubber tube from the tap that’s connected to the inlet manifold of the carburetor. Check its condition. If it’s cracked, hardened or loose, it will cause an air leak and restrict fuel movement. If the diaphragm is damaged, the tap will not work.

#6: Fuel Pump

Most 2-wheelers use gravity to feed fuel to the engine. Some high end motorcycles come with electric fuel pumps. When you switch on the power of the machine you will hear some clicking noises. This means the pump is active. If not, then check the wiring, battery output. Also, check the tubes leaks or damage.

#7: Fuel Cap Ventilation

Your 2-wheeler has fuel in the tank but fuel flow has stopped. What to do? Don’t panic and start from the top with the fuel cap. All fuel caps have pin holes to allow for breathing during vapor build-up due to heat or movement. If the pin hole is blocked, it will create a vacuum and prevent fuel flow. Clean it with a pin. Usually, it’s an easy fix.

#8: Air leaks

In a fuel supply set-up, air leaks can happen at many places. A loose carburetor manifold will allow outside and unwanted air to be sucked in and will not allow the engine to start. The manifold has to be air tight and if needed check the rubber ‘O’ ring that’s provided. Replace it to save inconvenience and tighten the manifold, carburetor or fuel injector properly with recommended packing inserts. Never use silicon; it will block the jets in the carburetor and block fuel.

#9: Carburettor Issues

A jammed throttle body or broken cable may also cause an engine to malfunction or not allow it to start despite fuel and spark. This will require professional help and defective part replacement.

Exhaust System Problems

#10: Carbon Residues On Exhaust Baffles

In monsoons, it’s no secret that some riders take the risk of wading through flooded roads without bothering about the consequences. Water can seep into the engine through the air filter or silencer. If the engine stalls, do not attempt to restart the engine. Any amount of water inside will cause the engine parts to malfunction. Water has to be removed altogether.

Over a period of time and use, especially in two-stroke engined motorcycles, silencer baffles will get choked due to the accumulation of carbon residue from burnt fuel.

As a result of this extreme condition, the engine will have difficulty in starting or will not fire at all. Silencer choking in four-stroke engines is rare unless the engine is in poor shape and burns oil.

Electrical Issues

After the fuel issues, you may have to focus on possible electrical faults if starting problem persists. These can be hard to identify without proper knowledge and tools.

#11: Switchgear

Switch on the main ignition and also ensure the emergency kill switch (usually located on the right hand side switch assembly next to the throttle) is in the ‘ON’ position. All the systems should become active. Some riders forget to check the switch position and fear for the worst. It could be a simple power on-off matter. If there’s no power, then check the fuse box and battery terminals.

#12: Safety switch

Some of the newer generation motorcycles and scooters have a safety cut off switch fitted to the side stand. If the side stand lever is down, the switch will deactivate the ignition system. The side lever must be up for the connection to continue.

#13: Spark plugs

Spark plugs are key components in an engine for prompting combustion. This is the first place to check if the engine doesn’t start. Begin by removing the spark plug cap so that the HT wire is exposed. You can take out the spark plug if you wish for this test. Crank the engine and see the spark from the HT cable by taking it close to the engine body.

If the spark is sharp, bright and blue, then you are fine. If its yellow, then it means the power is not enough to cause the spark plug to function as it should. If there’s no spark coming, then there could be other problems.

If you have current on the lead, then put the plug cap back and check the spark plug using the same process. If there’s no spark on the plug with the cap on, then either the cap or spark plug is at fault. Replace it with a new one.

If there’s spark on the wire and not on the spark plug, then the spark plug might need cleaning or replacement.

Check the condition of the wire terminals at the high tension coil end. If there’s evidence of oxidation or corrosion, clean it up and reconnect the HT terminal wires. Also, check for cracks or damages on the high tension lead. A faulty HT coil will have to be replaced if it doesn’t perform 100 per cent.

#14: CDI module

As a key part of the ignition system, the CDI (capacitor discharge ignition module) could be at fault. Usually, these are epoxy sealed units and are built to be durable with long service life. Although, they rarely fail, in most cases its failure can be attributed to problems created when the OEM wiring harness is tampered. Take professional advice and assistance to rectify problems.

#15: Contact breaker points

In older generation motorcycles that used contact breaker set-ups, the timing plate that hosts the contact beaker set-up, condensers, cam needs to be checked and reset. Faulty and worn out parts may need to be replaced. Here, professional advice is recommended.

#16: Ignition timing

If the ignition setting is not correct, the engine will not fire. This will require re-setting the timing using specialized timing equipment like strobe, timing disc etc. This aspect is applicable for all engines irrespective of type. This situation can happen after an engine has been overhauled.

#17: Clutch switch

Especially in high-powered machines, this switch ensures that the engine will not start if the motorcycle is in gear. It’s more of a safety kit and if found defective will stall the power needed to start the engine.

#18: Pick-up coil

Machines with electronic ignition systems use pick-up coils that send signals to the CDI unit. The signal is reached to the ignition coil via the command module unit for the spark to be generated. If the pick-up coil fails to send the signal, the CDI will not work. Seek professional help if the coil has to be replaced.

#19: Wiring harness

If electrical issues develop in the motorcycle or scooter, road side garages tend to offer temporary fixes. The manufacturer installed OEM wiring, crimping and connectors may be tampered and cause electrical problems later and damage equipment. In older machines over time, acid from the battery moves into the wiring harness and creates resistance in them.

This results in a drop of voltage even if the battery is perfect. In such a case, the ignition module, HT coil may not get enough current for it to perform properly. In such a case, the wiring harness needs to be changed altogether.

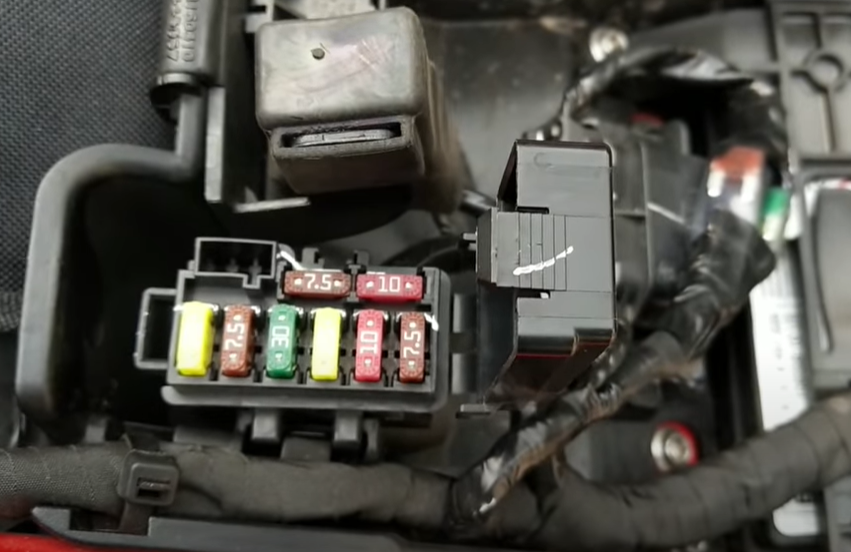

#20: Blown fuse

If the battery is OK and there’s sufficient charge with current coming after checking it with a multimeter or gauge (never short the wires as it damages the battery) and still there’s no current at the switches, it’s a good idea to check the fuses in the fuse box. In most motorcycles, fuse boxes are usually located under the seat or behind the side panels. A blown fuse or a loose fuse could be the sole source of the electrical continuity fault.

#21: Faulty starter motor

Some motorcycles come with starter motors and some don’t. Then you have motorcycles and scooters with both a self starter and kick start lever. Some modern machines have given way to electric starter motors only. A starter motor will not be able to crank the engine if its armature is damaged or carbon inserts worn out.

You push the starter motor switch and just hear a clicking sound but the starter motor seems to trip. This could mean that the starter motor relay isn’t working. Relays prevent high amperes damaging the coils or armature when in contact. Relays have to be replaced if they don’t work properly.

In 2-wheelers with both starter motor and kick start lever, in the situation where the starter motor fails, the only way out is to rely on the mechanical kick starter lever. Even in the case of a weak battery, the kick starter will enable the motor to start and help recharge the battery to some extent.

Mechanical Issues

#22: Jammed or damaged engine components

Although motorcycle/scooter engines are designed to perform for many kilometres of trouble-free riding. In cases of extreme overheating, the pistons can get damaged and stall the engine.

Battery Problems

While batteries are part of the electrical systems, we felt battery merited its own section since they are such a vital components in a motorcycle and affects almost all the power components.

While we list the battery problems below, here is our detailed post on starting problems when the battery is doing fine.

#23: Dead Battery

In motorcycles using battery powered ignition systems, any low voltage output will impact the spark outcome. A flat battery will not be able to power the electrical and electronic equipment needed to start the engine. The 12 volt battery must dispense the correct amount of current (volt and ampere) to enable cranking of the engine. However, in real-time, if voltage is low, the starter motor will be under strain to work properly.

Leaving the ignition switch or lights on when a machine not in use by oversight will deplete a healthy battery.

It’s natural for batteries to weaken over a period of time.

Common issues that can be resolved are a loose terminal (+/-) connection or replenishing the water inside the battery cell if it has dried out.

If a motorcycle is unused for long periods of time, it is recommended to have it disconnected and if possible put on trickle charge.

When reconnecting a battery, always remember to connect the terminals (+/-) correctly. Wrong polarity can cause electronic components like the ignition module to fail permanently.

#24: Jump starting

Assuming fuel and fuel systems are fine and the starter motor struggles to crank the engine because of a depleted battery, any 2-wheeler can be jump started successfully. For this you will need a set of jumper cords and a strong 12V supply from another battery source. Connect the negative terminal first from the donor battery to the flat battery first. Thereafter, the positive terminals. Switch on the ignition key and give it a try. If the engine still refuses to start, then a bump starting method may have to be used.

#25: Bump starting

This is a physical method of starting any geared motorcycle. The motorcycle is put in second or third gear and the rear wheel is given momentum by pushing the bike with the clutch depressed. When some momentum becomes available, release the clutch and let the engine rotate. It should start in a few attempts if you are doing it for the first time. If you are a scooter owner, this method will not work as the transmission is belt driven and not geared.

Conclusion

From a simple problem like a blown fuse or leaving power on and depleting the battery accidentally overnight to water contamination, petrol issues and ignition component failures, so many avenues can be responsible for the engine not working. So always expect the unexpected and be prepared to invest in extra time and resources.