Piston rings are cast iron ring strips fitted on the piston’s outer diameter.

Their main purpose is to close the gap between the cylinder walls and the piston to ensure the fuel mixture does not enter the crankcase.

That’s just not it.

They have a few more functions as well.

So, let’s dive in detail on piston rings’ engineering. Their roles. Their importance in motorcycles (can’t run without them). And their lifespan.

What are piston rings and how do they work?

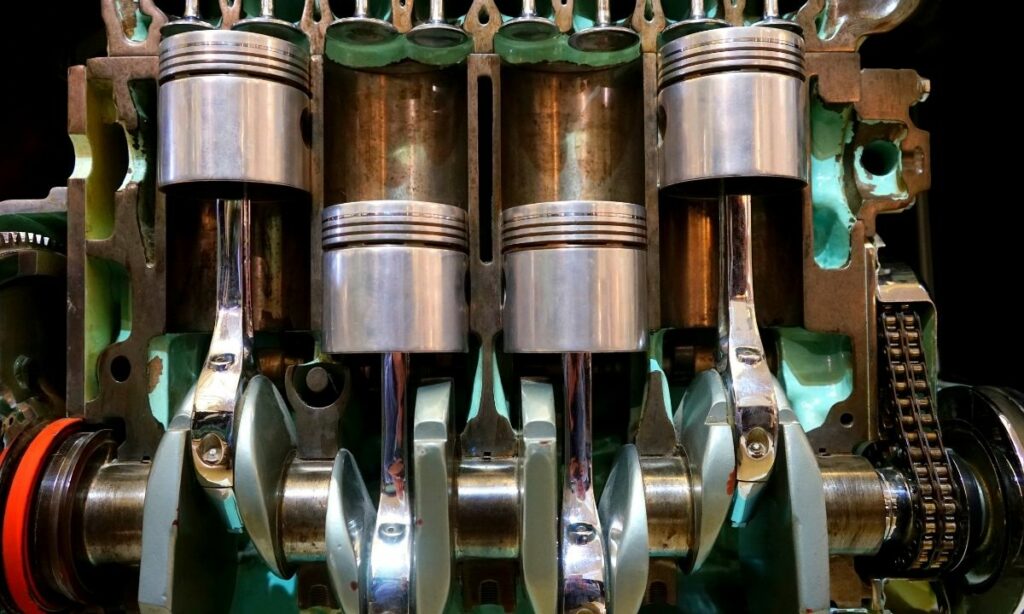

Piston rings are cast iron ring strips attached to the piston grooves along its outer walls.

The piston has grooves for piston rings and usually, there are three (sometimes two) grooves to accommodate the three piston rings along its outer diameter.

That’s good. But what do they do?

What work do piston rings do?

Piston rings close the gap between the cylinder walls and the piston.

This gap sealing ensures the fuel mixture does not enter the crankcase. The rings create a divide between the crankcase and the combustion chamber.

Now, why don’t we have the pistons directly closing the gap with cylinder walls?

Pistons cannot directly close the gap with cylinder walls because – in case of thermal expansion, the piston will seize the cylinder – resulting in engine damage.

Functions of piston rings in an engine

There are three main functions piston rings play in a motorcycle engine:

First, piston rings seal the gap between the piston and the cylinder walls.

This closing helps to prevent the fuel from leaking.

Without the piston rings, the fuel mixture would leak from the combustion chamber into the crankcase.

They keep whatever is in the combustion chamber out of the crankcase and whatever is in the crankcase – out of the combustion chamber.

Second, piston rings facilitate heat transfer between the piston and the cylinder.

The piston is connected to piston rings and piston rings are connected to cylinder walls.

As a result, the heated piston due to the heat generated in the combustion chamber transfers its heat to the piston rings. Which, in turn, transfers it to the cylinder walls.

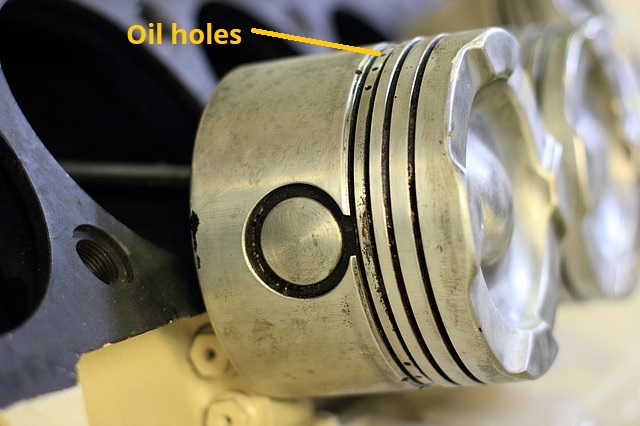

Third, piston rings help in oil flow across the piston walls to keep the piston lubricated.

The piston has oil holes right below the piston rings.

The oil in the crankcase moves up and the piston rings block them from entering the combustion chamber. And also force them to move through the oil holes.

As a result, the oil moves through the oil holes in the piston and lubricates both the outer and inner piston walls.

This helps in a smooth translating motion for the piston along the cylinder walls. Thereby transferring the energy produced in the combustion chamber to the crankcase smoothly.

What material are piston rings made of?

Piston rings are made of cast iron alloy.

Cast iron is a subset of iron-carbon alloys with carbon content making up more than 2% of the alloy.

So why is cast iron used in piston rings though? Why not other materials?

Cast iron is used in piston rings mainly because it provides strong wear resistance and offers excellent machinability.

That’s why most engineering and automotive materials use cast iron.

Kid you not. Cast iron is one of the most used engineering materials out there.

Any strong automotive component you take, chances are it’s most likely made of cast iron.

Just like Intel used to market themselves how they were inside all computers, you can say the same about cast iron. They are inside almost all automotive components.

Desired material properties for piston rings

When piston rings are manufactured, here are the main required properties of the material that piston rings will be made of.

- Strong wear resistance: As the piston moves up and down every combustion cycle, the piston rings will continuously brush against the cylinder’s inner walls throughout these movements.

- Good elastic properties: You don’t want the piston ring to be too brittle and should be able to expand if subjected to high temperatures.

- High heat resistance: The combustion chamber burns the fuel and generates an immense amount of energy and heat. The piston rings should withstand high temperatures.

In short, the piston ring material should have strong wear resistance, good elastic properties, and high resistance to heat.

Cast iron fits the bill mostly.

Add to it they have good tensile properties and excellent machinability.

We say ‘mostly’ because cast iron does not have great elasticity.

They are too brittle.

And that’s why:

Alloying materials are used in cast iron

While cast iron fits most of the bill as a piston ring material, it falls short on elasticity.

Cast iron is too brittle to satisfy the required elasticity requirements for piston rings.

That’s why alloying elements like silicon, manganese, and molybdenum are added to cast iron.

Adding alloying elements to cast iron helps in 2 ways:

- Adds elasticity since cast iron is too brittle to function as piston ring material

- Improves the wear resistance of cast iron

Alloys are a beautiful invention. It’s almost like any alchemy. 😉

Usually, silicon, manganese, and molybdenum are the elements alloyed with cast iron for piston rings.

In addition, copper and tin are sometimes added as well depending on the manufacturer.

Piston rings manufacturing

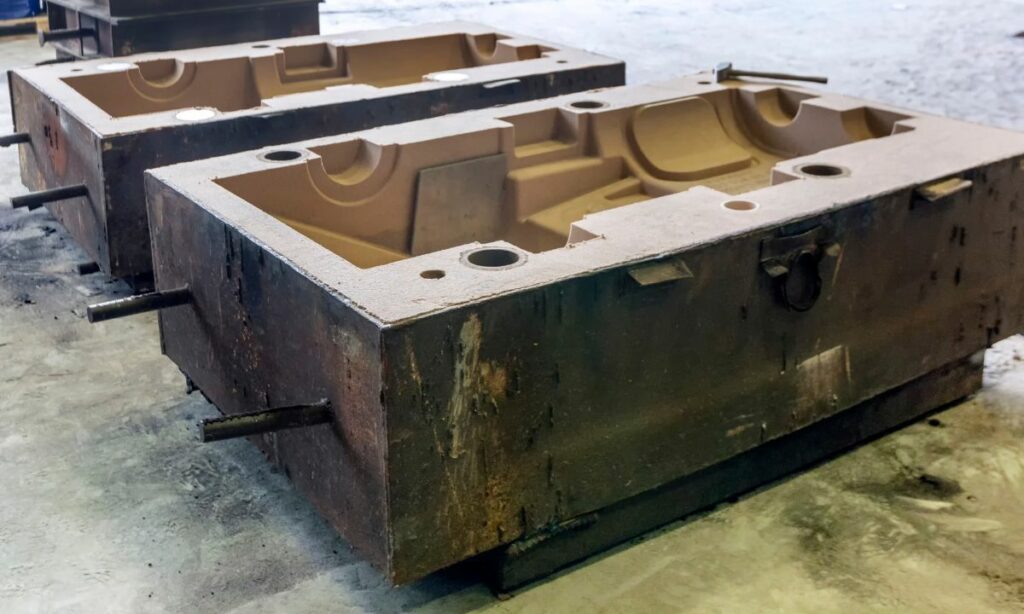

Piston rings are manufactured as a combination of casting and machining.

Typically, a cast iron cylinder block is either sand cast or cement cast.

Die casting is usually not preferred since cast iron itself has such high tensile strength.

Once you get the casted cylindrical cast iron block, you bore the cylinder to get a tube with defined inner and outer diameters.

Then, you come along with a parting tool and machine the tube at the required thickness to get the piston rings.

Lastly, each piston ring will have a clearance gap.

The gap can be created through various methods. Using a tapered cylinder and expanding from within to put pressure and break the ring is one of the used methods.

For more details on how piston rings are made, here is a video.

The three types of piston rings

The three piston rings placed on the piston’s outer diameter are:

- Compression ring

- Middle ring

- Oil scraper ring

The compression ring seals the combustion chamber from the crankcase.

The oil ring helps in engine oil lubrication along the piston walls.

The middle ring performs a bit of both. And acts as a backup for the other two rings.

For a more in-depth view, here is our article on each of these ring types.

Can an engine run with damaged piston rings?

An engine cannot run without piston rings. Or even damaged piston rings.

Broken piston rings result in damaged and worn-out piston and cylinder walls in no time.

Here is what will happen if you run an engine without piston rings.

First, there won’t be enough power generated in the motorcycle.

The pressure will be lost in the combustion chamber for the piston to move up and compress the fuel mixture. There are no piston rings to seal and preserve the pressure here.

Second, the fuel mixture will leak across the cylinder walls and piston outer diameter.

The fuel will be lost in the crankcase and cannot be used to generate power. Huge loss of fuel, power, and mileage there.

Third, as the piston moves up and down the engine oil will enter the combustion chamber and get burnt.

The engine oil which is present in the crankcase lubricated the crankshaft and other components encased in the case. Regular consumption of the oil will result in low engine oil levels in no time.

And last, expect lots of piston slapping, scratching, and damaging of the piston along the inner cylinder walls.

Without piston rings, the to and fro piston motion won’t be smooth and guided. The gap between the piston and cylinder walls will result in metal-to-metal contact – damaging both these components.

In short, running an engine without piston rings is totally a bad idea since it will damage both the piston and the cylinder walls – not to mention, loss of fuel, engine oil burning, loss of pressure, and hence low power and mileage.

How often should you replace piston rings?

If your engine has run more than 100,000 miles, then probably it is time to replace the piston rings.

Typically, piston rings last somewhere between 50,000 miles to 250,000 miles depending on their maintenance.

On average, the life expectancy of piston rings is around 100,000 miles. And that’s the time to replace them.

FAQs

A: Here are the symptoms of a bad piston ring in an engine: excessive engine oil consumption; white smoke from the exhaust; low compression in the engine; decreased power and acceleration; and piston slapping.

A: Here are the main causes of piston ring failure: low-quality engine oil; air filter letting in dust; oil filter not working right; engine blowby; fuel flooding in carburetted engines.

A: The piston rings cost around $50 to $200. But the replacement cost of piston rings is more than $1000. The labor charges will be too high since piston ring replacement is labor-intensive and can take 8 to 10 hours.

Before you go…

Here are a few more posts on piston rings: