For a long time, I thought all the piston rings were the same. Kinda same.

Sure they have their differences. But I was of the opinion that their roles are the same.

So it was a surprise when I learned each piston ring on the piston is of a different type. And performs different functions.

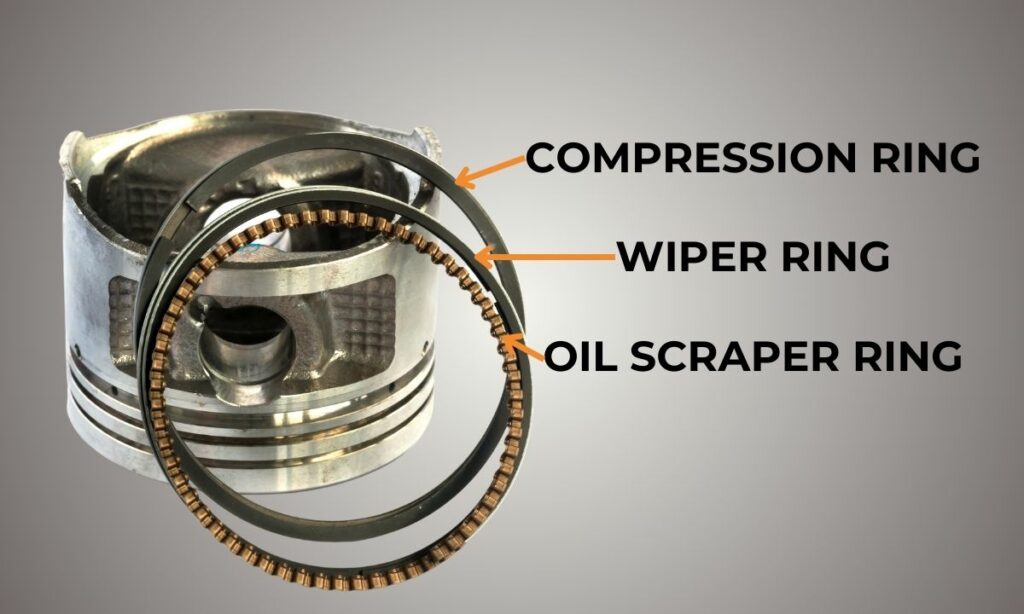

So, what are the types of piston rings? There are three piston rings placed on an engine piston.

- Compression ring

- Wiper ring

- Oil scraper ring

Let’s discuss the roles of each of these piston rings one by one.

#1. Compression Ring

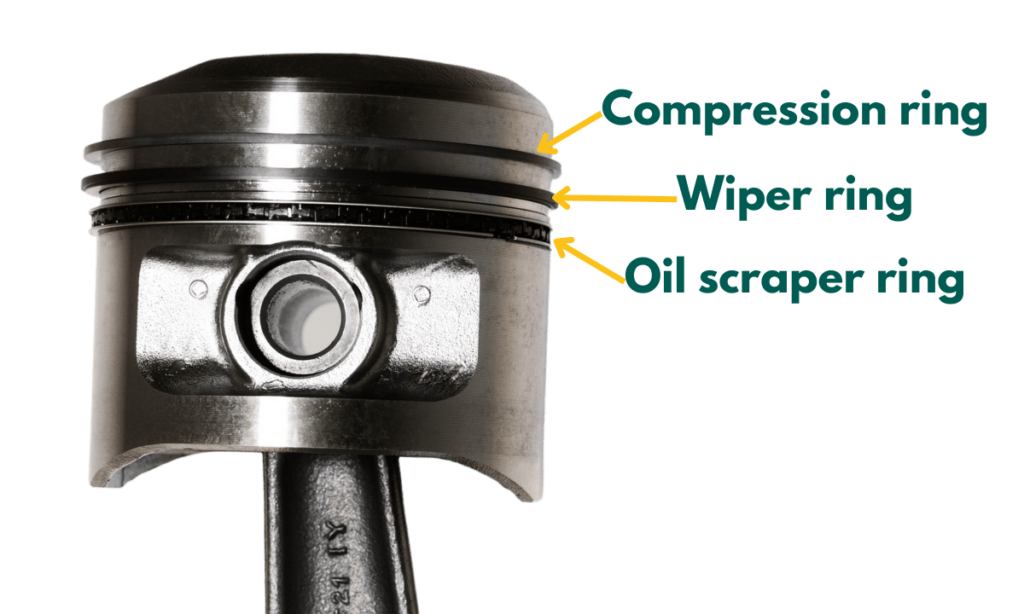

The compression ring is the top-most ring in the piston attached to its outside diameter.

The main function of the compression ring is to seal the gap between the piston and the cylinder walls.

Sealing this gap with the outer diameter of the piston and the cylinder walls ensures that the fuel mixture in the combustion chamber does not move down to the crankcase. And not cause low compression and power.

In addition, this sealing also makes sure that the engine oil in the crankcase, used for lubrication, does not move up into the combustion chamber as well.

If the oil did move up, it would get burnt.

The engine oil moving into the combustion chamber and getting burnt is bad news.

This effectively results in excessive oil consumption in the engine, leading to low engine oil levels.

So, essentially the compression piston ring ensures that the combustion chamber and the crank case are segregated.

Put simply:

The compression ring is like a wall. Moving wall albeit.

This wall separates the combustion chamber and the crankcase.

The combustion chamber has fuel. The crankcase has oil. And the compression ring makes sure these two do not mix.

The air-fuel mixture in the combustion chamber is not allowed to trickle down into the crankcase and the engine oil is not allowed to move up into the combustion chamber.

As a result, the compression ring helps in:

- maintaining high compression in the combustion chamber

- high power and acceleration in the vehicle

- no unnecessary burning of engine oil

Ever thought a small ring could achieve this many feats? 😉

#2. Wiper Ring

The second ring or the middle ring is called the wiper ring.

This ring is an all-rounder of sorts – performing the functions of both the compression ring and the oil scraper ring.

So, essentially, the wiper ring helps in sealing the combustion chamber from the crankcase as well as guiding the engine oil back down to the crankcase.

While it may look like the middle ring is just there as a backup for both the compression ring (the top one) and the oil scraper ring (the bottom one), I cannot stress its importance more since it performs the function of both the other rings.

If the compression ring is failing or not performing, then the wiper ring acts as the primary seal between the combustion chamber and the crankcase.

Thus, not allowing the air-fuel mixture to enter the crankcase and maintain engine performance.

On the other hand, if the oil scraper ring is not working, the wiper ring will again perform to guide the engine oil down back into the crankcase through the oil holes present below the oil scraper ring.

This helps in keeping the crankcase component and the piston lubricated and cooled down sufficiently.

That’s why the wiper ring is such an essential component since it acts as the backup for both the compression ring and the oil scraper ring.

#3: Oil Scraper Ring

The main function of the oil scraper ring is to guide the engine oil scraping along the piston’s outer surface back into the crankcase.

The engine oil lubricates the piston as well as all the components within the crankcase.

And the oil is essential for the engine since it performs two functions – i) lubrication and ii) cooling of the components.

Without engine oil, the engine will not perform well. Plus, there can be harmful effects on the motorcycle components.

That’s why the oil scraper ring which helps in guiding the oil along the piston as well as into crankcase to lubricate and cool down the components is such an essential component in itself.

Now, how does this oil scraper ring help exactly?

First, what the engine oil does is it moves up along the piston’s outer diameter as a result of the piston’s up and down movements.

The oil scraper ring barricades further upward movement of the oil and forces it to move downward.

Now, this is where things get interesting.

The oil scraper ring although forces the engine oil to move downward, it does not necessarily mean along the piston surface.

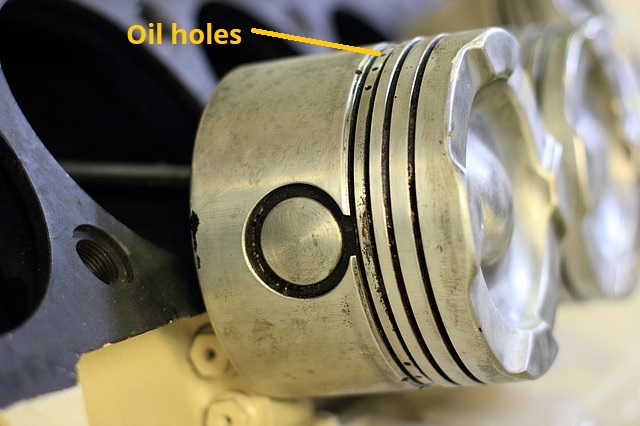

There are oil holes on the piston right below the oil scraper ring.

These holes allow the engine oil which is forced to move downward to enter the crankcase through these holes.

Thus, the engine oil which was moving along the piston’s outer surface is forced back down into the crankcase by the oil scraper piston ring.

That’s why the oil ring is so vital for engine oil movement within the crankcase.

The oil scraper ring prevents the crankcase components from heating too much or getting worn out by facilitating smooth oil movements.

Other functions of all three piston rings

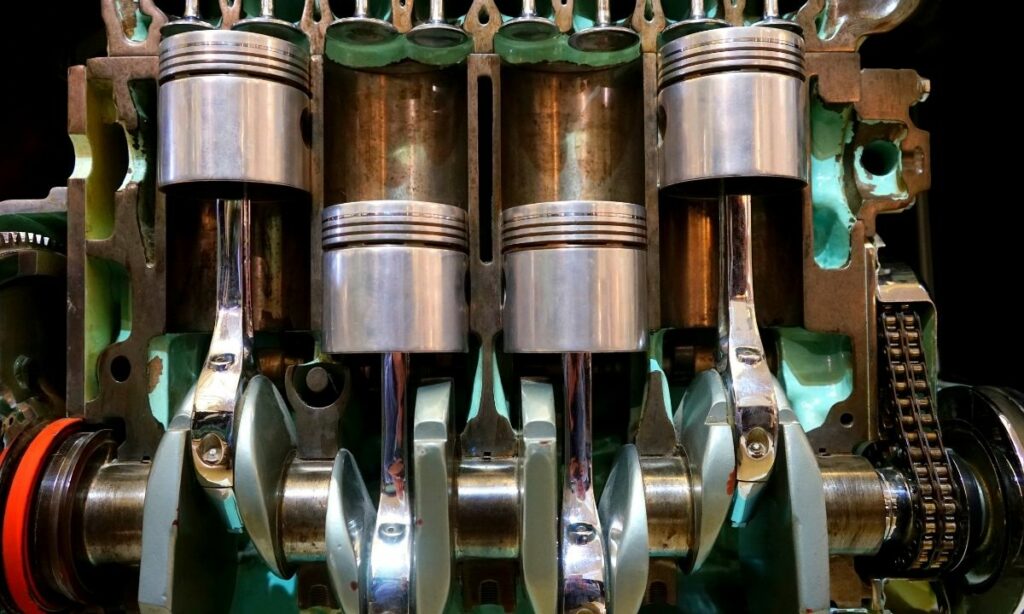

Apart from their designated functions, these piston rings together as a whole perform certain functions as well.

The foremost being – heat transfer from the piston to the cylinder walls.

All three piston rings are connected from the piston’s outer diameter to the inner cylinder walls.

The piston gets heated due to its continuous contact with the combustion chamber.

As a result, the piston needs to be cooled down and the heat should be transferred away.

This is where all three piston rings come in handy.

The rings transfer the heat from the piston to the inner cylinder walls – thus reducing piston temperature.

Other functions include maintaining high compression in the combustion chamber, higher power output in the engine, maintenance of engine oil levels, and overall, maintaining optimum engine performance.

Why do few pistons have only 2 piston rings?

2-stroke motorcycle engines have pistons with only two piston rings.

Why is that?

In 2-stroke engines, the fuel and the oil mix with each other. There is no need for segregation. And hence, no need for an oil scraper ring.

That’s why in 2-stroke motorcycle engines, there will be only two piston rings on the piston.

To Summarize

The 3 types of piston rings are – compression ring, wiper ring, and oil scraper ring.

The compression ring is the topmost ring in the piston attached to its outside diameter. The main function of the compression ring is to seal the gap between the piston and the cylinder walls.

The wiper ring is the second ring and helps in sealing the combustion chamber from the crankcase as well as guiding the engine oil back down to the crankcase.

The oil scraper ring is the bottom-most ring. It guides the engine oil scraping along the piston’s outer surface back into the crankcase.

Apart from their designated functions, these piston rings together as a whole perform certain functions as well.

These include – heat transfer from the piston to the cylinder walls, maintaining high compression in the combustion chamber, higher power output in the engine, maintenance of engine oil levels, and overall, maintaining optimum engine performance.

Before you go…

Here are a few more related posts for you: