Engine problems are a pain. An engine is the heart of a motorcycle. Any problems there is a big concern.

So when the engine bogs down while accelerating you need to look for the concern areas.

The trouble spots for a motorcycle engine bogging down when accelerating include:

- Air filter

- Fuel and fuel delivery system

- Cooling system

- Exhaust

- Spark plug

- Engine

- Clutch

Let’s deep dive into these problem areas and how to address them.

Why motorcycle engine bogs down when accelerating?

Most of us are aware that for getting peak performance from your motorcycle’s engine there are four key elements that contribute namely: Air, fuel, compression, and spark.

Besides these, there could be other mechanical issues that have their roles in the performance.

So, when a motorcycle seems to be losing power or running out of steam, especially on uphill stretches, then these are some of the tell-tale signs that all is not well.

Each one of the functional areas in an engine is an independent system by itself yet all of them play important roles when it comes to extracting and delivering power from the engine.

Assuming the engine is mechanically in good order, we take a look at the above system areas and examine the parameters that are involved.

There can be simple problem areas that can be handled as a DIY job or if complicated, specialist help is recommended.

Let’s take a look at possible troublespots

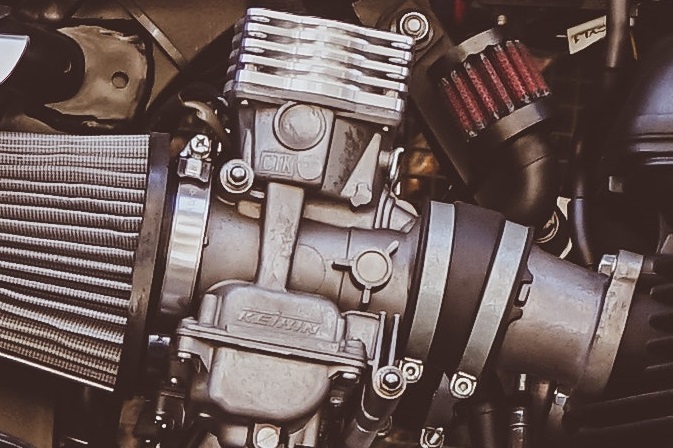

# 1 Problem area: Air filter

Air filters will clog up with time as the motorcycle is being used. When it will happen depends on the riding conditions of the machine.

Motorcycle filters will clog faster in dusty off-road riding conditions when compared to cleaner on-road rides.

Interestingly, the performance of an air filter in a motorcycle also depends on the era it belongs to in most cases. However, there are exceptions where old filters have been modified or retrofitted with aftermarket products.

Most older bikes are found fitted with dense foam filters. They are considered quite efficient as they are able to filter out air quite efficiently.

For many off-road biased bikes that have to face harsh conditions like dirt and fine dust, foam air filters are preferred as they can be washed and reused.

Some motorcycles even came with an oiled foam variant. They work even better since the thin oil film helps capturing more minute particles. But they will need frequent cleaning.

Paper filters are fitted in most modern motorcycles as they are cheaper and easy to maintain or replace. All one needs to do is blow compressed air on it to clear the dust caught in it. Paper filters are usually replaced when the motorcycle goes into its service schedule if found clogged.

Performance machines are usually fitted with cotton fabric air filters. Compared to foam or paper, they are stronger, breathe better, and are fine enough to filter the air really well. They are preferred as they don’t restrict the volume of air after filtration.

Cotton air filters can be cleaned with appropriate solvents and reused.

Out of fashion are the wire mesh filters used on classic or vintage motorcycles that were soaked with oil as they were not so efficient.

Choked air filters in a contemporary motorcycle will impact the performance of the airflow sensor as it gets dirty and will cause the electronic throttle body to malfunction and limit engine rpm. This means less output from the engine even when demanded.

The second area that needs to be addressed is the slack in throttle cables in motorcycles with mechanical throttle cables that can loosen over time. If the cable is slack, the butterfly flap in the CV carburetor will not fully open and will restrict airflow.

Likewise, in motorcycles with throttle slide-operated carburetors, slack in cable means the slide unit movements are restricted and hence the engine will not get enough air inside the combustion chamber when demanded. In this situation, the engine will make less power unless the fault is rectified.

Solution: Most dirty air filters (foam, paper, or cotton) can be cleaned or replaced.

Throttle cable slack can be corrected as most cables have adjusters to tighten them. When readjusting, make sure you don’t overdo it as it may stress the cable and may cause it to fail later.

Skill level: DIY/Technical

Cost: Moderate

# 2 Problem area: Fuel & fuel delivery systems

The fuel delivery system in older motorcycles was gravity fed via manual or vacuum-operated petcock.

In modern machines, especially those fitted with electronic fuel injection systems, fuel is sent through a dedicated pump to either the fuel injector or carburetor. When the quantity of fuel demanded by the engine isn’t met, then there’s a drop in power delivery.

Several factors can be responsible for this — ranging from a blocked ventilator pipe in the fuel cap, choked fuel pipe or fuel filter, or choked petcock filter (located inside the fuel tank).

A poorly performing fuel pump will also impair the performance of the engine.

Quality of fuel is also another key factor. Engines designed to run on leaded fuel tend to overheat when unleaded/blended fuel is used. Incorrect octane fuel will also lead to overheating and a drop in performance.

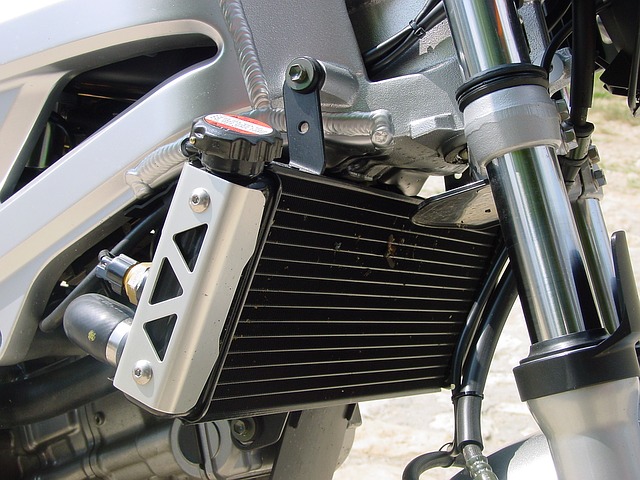

# 3 Problem area: Cooling systems

Overheating will also cause a drop in engine performance and output.

Oil and liquid cool systems in the machines are responsible for keeping the engine temperatures within working range. These will deteriorate after a period of time as the coolants lose their ability. The impact is felt gradually or immediately if there’s a blowout as a result of a ruptured pipe.

Liquid-cooled engines have scores of tiny pipes that circulate coolant inside the crankcase jacket. A radiator with thermostats activates the fan which in turn takes care of the heat exchange process.

Clogged water routes inside the engine will impair coolant circulation and affect temperature control. A faulty temperature sensor or thermostat can also be the cause of radiator fan malfunction. The fan itself could be defective and not working properly.

Solution: Most dirty or clogged radiators can be cleaned or replaced. Coolants can be topped or replaced. Faulty fans or thermostats will have to be replaced. For older engines, an engine flush could be helpful.

Skill level: DIY/Technical

Cost: Modest

# 4 Problem area: Exhaust

Another reason for engine bogging can be because of problems in the exhaust system.

Most modern motorcycles are designed to run on unleaded or ethanol-blended fuel. These machines are also fitted with catalytic converters that can get clogged due to the rich air/fuel mixture.

When the engine is running and hot, exhaust particulates build up that reduce or restrict exhaust gases causing pumping losses.

Older muffler units can rust inside and choke the filter elements (especially the perforated pipes that may perish as small parts) and thereby restrict them.

Solution

Clogged or damaged silencer/muffler units have to be replaced. Some catalytic converters can be cleaned but most have to be replaced at the end of their service life.

Skill level: Technical

Cost: High

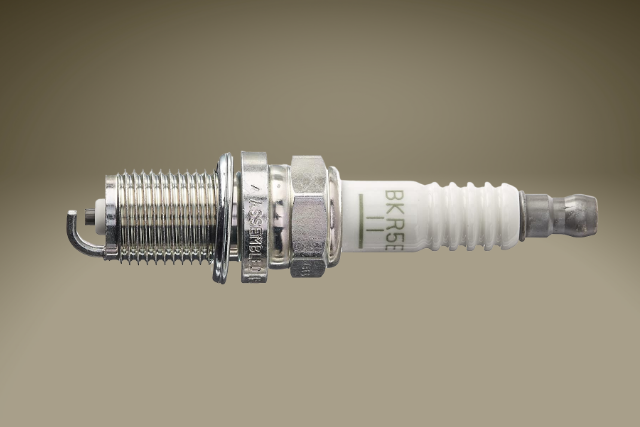

# 5 Problem area: Spark plugs

Dirty, fouled or worn-out spark plugs are known to hamper the engine’s performance and power output.

In multi-cylinder engines, a malfunctioning spark plug will result in a noticeable drop in power and a cylinder missing.

Dirty spark plugs can be cleaned and reused. However, worn-out plugs have to be replaced.

In the worst-case scenario, there have been instances when spark plugs don’t receive enough current from the electrical set-up of the machine.

Such a situation is rare when the generator that has specific stator coils for ignition fails.

Usually, in its construction, stator coils are insulated from external elements, but moisture can impact the coil’s output. When this happens, the amperes needed for the ignition system malfunction and hence there’s a significant drop in current output.

Low output voltage and amperes from the AC generator will not allow the Capacitor Discharge Ignition (CDI) unit to work as it is a vital piece of equipment that plays a crucial role in determining the intensity of the spark on the plugs besides ignition timing.

Likewise, a weak battery can also impact the DC CDI systems.

On older motorcycles that did not have electronic ignitions but had mechanical contact breaker point systems, the ignition timing had to be set manually for advance/retard. If set incorrectly, engine output will be impacted.

When generator technology wasn’t as advanced as what we experience today, some motorcycles of the 60s-70s were plagued with magnets losing their magnetic domains. In practice, it meant voltage output from stators would drop significantly resulting in power loss and no spark when the engine became hot.

Solution

While replacing spark plugs do ensure the correct specification ones are used.

Skill level: For spark plug change (DIY), for other ignition-related issues — specialist help may be needed

Cost: For spark plugs – moderate, for stator/generator — POA (price on application)

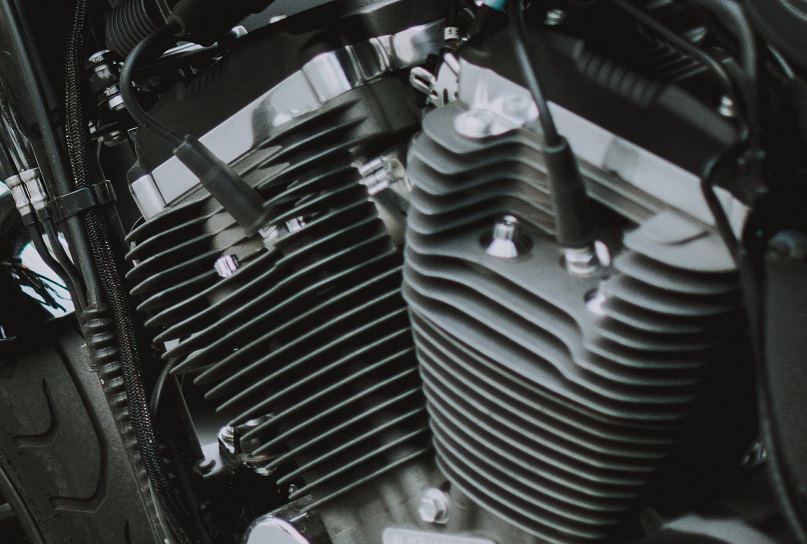

# 6 Problem area: Engine

Wear and tear of internal components of the engine is quite normal and piston rings are among the first to wear out. Excessive wear will result in blow-by and less compression.

That’s why manufacturers strongly recommend oil and filter changes for good lubrication performance and reduction of friction of piston rings on the cylinder walls. This service application will prolong the life of the engine.

Replacing them requires stripping the engine from the top end (cylinder head, jug/barrel).

Another component in the engine that plays a huge role in combustion is the valves. Carbon deposits on the walls over a period of time will have some form of impact on the intake and exhaust systems.

Even worse are worn-out valves, valve guides, and valve seats. Replacing them is part of an exhaustive engine rebuild that may need other parts to be replaced or refurbished.

Most motorcycles use port fuel injection and lubrication through intake valves that result in deposits that will not allow the valve to be seated properly. This can result in leaks or backfires besides loss of power.

Engine knocking is also one area that is often overlooked. Deposits in the cylinder walls and pistons can heat up and engine sensors will try to compensate for that by retarding the timing. This means the power output will drop because the spark plug is firing later.

Stuck or bent valves can also cause a lot of trouble for the engine. They will cause a significant drop in power, knocking, and expensive rebuild bills.

Solution

Replacing piston rings and valves will require specialist help.

Skill level: Technical Specialist

Cost: Varies

# 7 Problem area: Clutch

The clutch set-up is designed to transfer torque from an engine to the transmission.

The clutch assembly is made up of several parts like an outer clutch basket, friction, alternating steel plates, springs, and spring holders among other parts. Most modern motorcycles come fitted with wet clutches that are bathed in engine oil.

Clutch slipping is a common problem which means there’s too little friction, either due to worn or glazed friction plates or improper oil.

When this happens, the engine will rev higher, but the motorcycle speed will not correspond.

Solution

A worn-out clutch will have to be replaced with a new one.

Skill level: Specialist/advanced DIY

Cost: moderate to expensive