Gapping a spark plug is a simple albeit irksome task. But a spark plug gap that is too small or too big is not desirable at all for the engine.

So, how do you gap a spark plug? A spark plug can be gapped using any of these 3 tools and methods. These 3 tools widely used for gapping are:

- Coin gauge

- Feeler gauge

- Wire gauge

Although spark plug gaps are preset, you still have to gap to the right dimensions. That’s where these tools come in handy.

As for how each of these tools is used to gap a spark plug, let’s discuss them one by one.

#1: Coin Gauge

Coin gauge is the most convenient, and hence, the most popular tool used for spark plug gapping after service.

These coin-type spark plug gap gauges are circular in shape. Just like a coin. The thickness, however, varies along the circumference of the coin. The thickness measurement is provided by the readings on the coin.

So, a reading of 0.05 inches will have the same exact thickness at that point on the coin circumference.

Steps

As for how you gap the spark plug using this coin gauge, here are the steps:

- Hold the spark plug along the shell and the threads in one hand. You need to be careful with the spark plug here. Especially the electrodes.

- Take the coin gauge on the other hand. Place the gauge in between the center electrode and the ground electrode starting from the starting (and smallest) spot of the gauge.

- The coin gauge will start with a thickness of 0.01 inch or 0.02 inches. Start from there. The gap will usually be far higher.

- Slowly run the coin gauge in between the electrodes. Make sure you are rotating the coin gently since the center electrode should not be damaged.

- Keep running the coin gauge until you hit the resistance. Once hit, check the reading. That will give you the current spark plug gap measurement.

- If you need to increase the gap, run the coin gauge to a higher thickness slowly. Once the thickness is achieved to the desired level, run back the gauge and remove it.

- If you need to decrease the gap, use the coin gauge on the ground electrode and push it down. The gap would be smaller now. Run the coin gauge again to measure the thickness and adjust accordingly.

This method is easy and one of the most followed methods to gap spark plugs. It also helps that the process is intuitive and the coin gauge design itself feels common sense.

#2: Feeler Gauge

Feeler gauges are used to measure a gap width and are used in several engineering and automotive applications apart from spark plugs.

A feeler gauge is made up of several lengths of steel of varied and differing thicknesses. Each length of steel has a labeled thickness which can be used to measure a gap width.

Steps

As for how this can be used to gap a spark plug, here are the steps you can follow:

- Firstly, unlike coin gauges, feeler gauges only provide the measurement of the gap. And hence, the feeler gauge alone as a tool is not sufficient to increase or reduce the spark plug gap. You would need another tool like a hammer or a hard object to increase or decrease the gap by applying pressure on the ground electrode.

- Start with the feeler gauge and take the steel length whose thickness matches the required spark plug gap. If, for example, the required thickness is 0.05 inches, choose the length of steel with 0.05 inch reading.

- In case the required spark plug gap has an unusual width measurement, you can club different steel lengths to arrive at the required thickness. For example, say the required gap width is 0.035 inches. And the feeler gauge does not have the steel with 0.035 inches thickness, you can club two lengths of steel of, say, 0.02 inches and 0.015 inches to arrive at the required thickness.

- Once you have selected or arranged the feeler with the required thickness, place the feeler in between the central electrode and the ground electrode, i.e., the spark plug gap.

- If the feeler has lots of freedom to move in the gap, the gap is too high and needs to be reduced. Use a small hammer or a hard object and gently press it on the ground electrode to reduce the gap.

- If the feeler is not able to slide in the gap, the gap is too low and needs to be increased. Again, to increase the gap, gently pull the ground electrode with a sharp tool. The gap will be increased.

- Repeat the above exercise until the feeler gauge fits in the gap perfectly.

#3: Wire Gauge

Coin gauges have one major complaint against them. If you are not well versed with the tool, the coin gauge can potentially break the fine wire central electrode.

And wire gauges act as a perfect alternative for coin gauges if you are not too familiar with coin gauge handling.

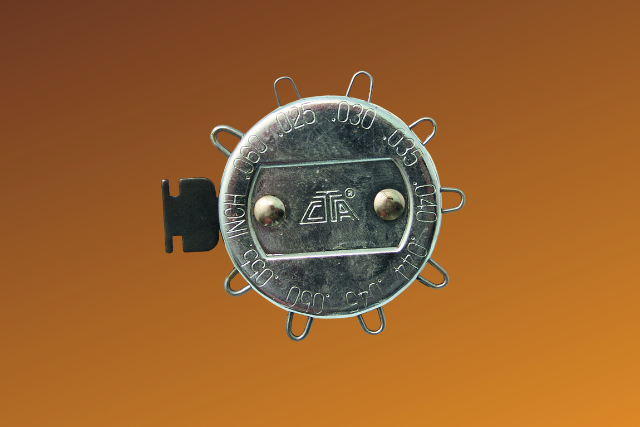

Wire gauges are again circular-shaped gauges with U-shaped wires attached along the circumference with a gapping surface attachment. The wires will have the exact same thickness as mentioned on the gauge readings.

Steps

As for gapping the spark plug using a wire gauge, here are the steps:

- First, you need to know the required gap measurements for your spark plug. You can check the user’s manual or look up the desired spark plug gap for your engine on the OEM website.

- Once you know the required gap, check the current spark plug gap with the wire. Use the required wire with the matching thickness and insert it in the gap between the electrodes.

- For example, if the required thickness is 0.05 inches, use the wire with 0.05 inches thickness and place it in the gap between the spark plug electrodes. If the wire can breathe between the gap, the gap is too high. If the wire can’t fit in the gap, the gap is low.

- If the gap is low, you need to increase the gap. This is where the attached gapping surface on the wire gauge comes in. Use this on the ground electrode to widen the gap.

- If, on the other hand, the gap is too wide and needs to be decreased, the process is even simpler. Tap the ground electrode on the surface of the wire gauge. And then gently press the plug so that the ground electrode reduces the gap.

- Repeat the above process and continuously check the gap thickness using the wire – until the gap equals the required wire thickness.

Conclusion

In the end, you can use any of these three tools – coin gauge, feeler gauge, or wire gauge to gap a spark plug.

Coin gauges look the most effective and clean way to do it. But, if you are not too familiar with the tool, the central electrode tip might break if you handle it rough.

The feeler gauge is simple but you need other tools to widen or reduce the spark plug gap. The feeler gauge in itself is only a gap thickness measurement tool.

Wire gauge is another viable alternative. While the handling is not intuitive unlike the coin gauge or the feeler gauge, they don’t have as many complaints of tip breakage as coin gauges. And they don’t need extra tools like the feeler gauge.

On the other hand, what are not acceptable tools to gap the spark plug are normal coins (I have seen this far too many times), a big hammer, a screwdriver, or any other automotive tools that have no business near a spark plug.